Machining & Manufacturing Services

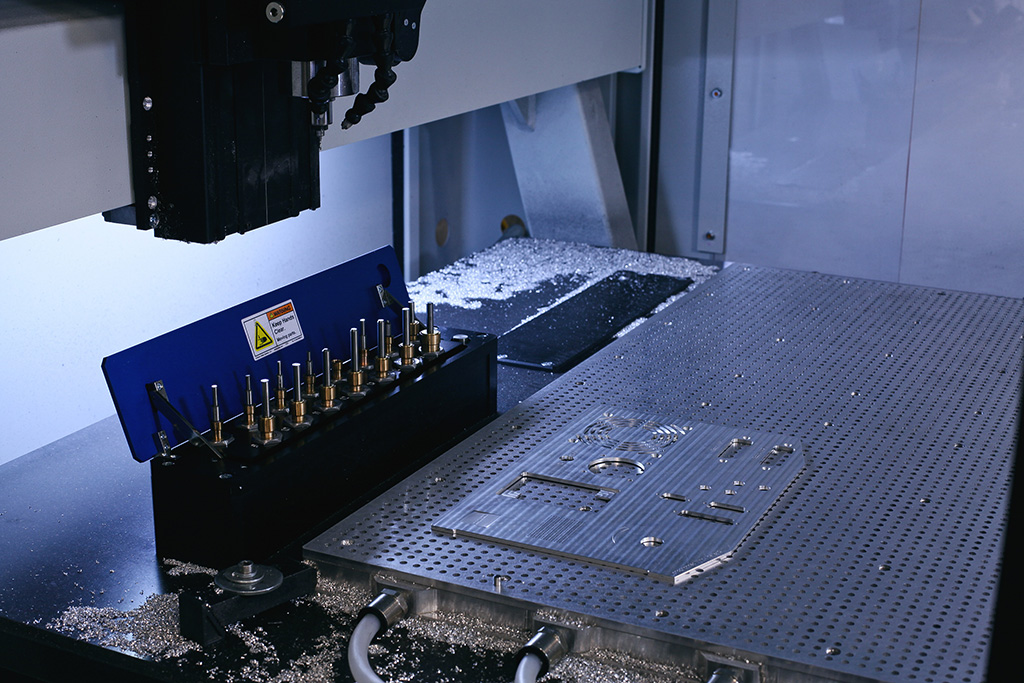

DataPro specializes in small to medium-sized projects that require precision manufacturing, tight tolerances, and quick turnaround times. Our goal is to complete your project entirely in-house, and our state-of-the-art manufacturing facility has the flexibility to do so.

Our primary production capabilities are CNC milling, CNC lathing, and sheet metal forming. Post-processing capabilities include: coating, marking, assembly, inspection, packaging, and shipping.

We specialize in machining a wide range of tool steels, titanium, and aluminium alloys, and can assist in sourcing and processing these specialty materials to your exact specifications:

- Aluminum Alloys: 5005, 6061 and 7075

- Carbon/Alloy Steel: 1018, 1025

- Stainless Steel: 303, 304, and 12L14

We can also work with an array of other materials including, but not limited to:

- Plastics: delrin-acetal, acrylic and ABS

- Copper alloys (such as bronze and brass)

Project Gallery:

Capabilities:

3 and 4-Axis Precision CNC Machining

Our machines can reliably deliver parts accurate to an industry-standard 0.005" tolerance with zCAT CMM inspection.Micro Drilling

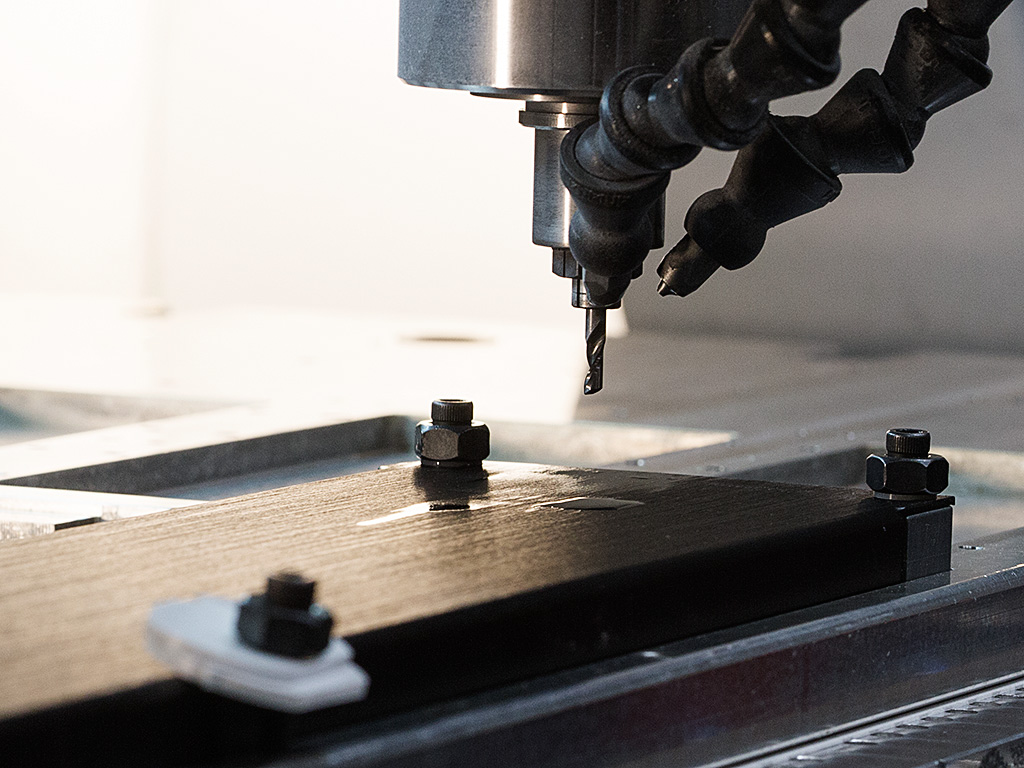

With spindles capable of 60,000 rpm, we can accurately and efficiently drill holes as small as 0.001" in diameter.In-Process CNC Inspection

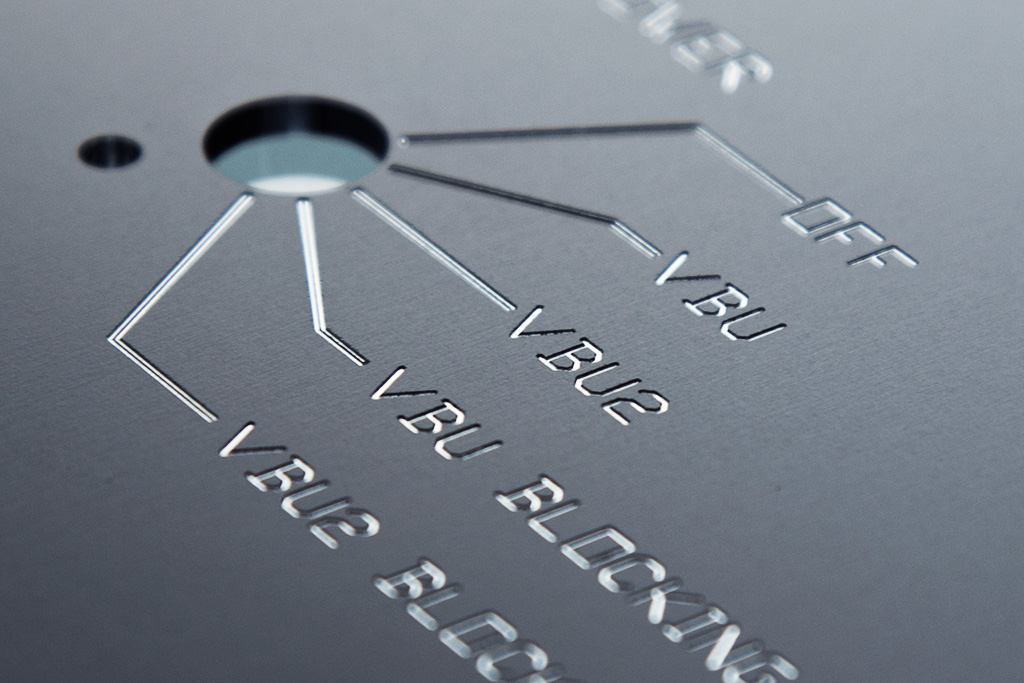

We use a Renishaw probing system for early defect detection and prevention.Mechanical Engraving

We achieve highly controlled engraving depth, compliant with MIL-SPEC requirements.Laser Marking

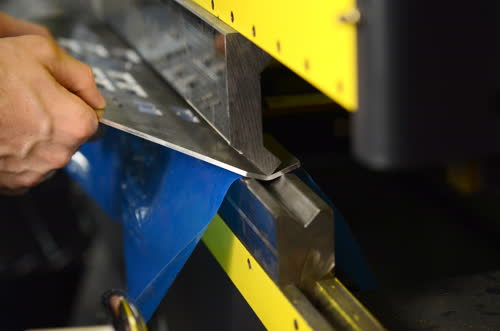

Precision laser marking, logo and graphic conversions, and more! For clean lines with maximum precision, laser marking is the perfect solution. Take a look at our Laser Marking Sample GallerySheet Metal Bending

We utilize a hydraulic press brake and a box and pan brake, which is ideal for producing custom enclosures with up to 0.125" thick material.100% Part Quality Control

Our QA team conducts thorough inspections as part of our ISO-certified quality assurance process. We’re also happy to implement customer-defined inspection and testing procedures to ensure your exact standards are met.Abrasive Media Blasting

We offer a range of finishing options including tumbling and abrasive media blasting (sandblasting pictured).Finishing Options

- 4 Axis indexing

- Anodizing (including MIL-A-8625)

- Powder Coating (including MIL-PRF-24712)

- Painting